This guide explains how to enable features for managing backorders and schedule them to run effectively. It is intended for system administrators.

When shipments are short due to low inventory, aACE can help you manage backorders. After you set up this feature, your system watches for inventory replenishments, then automatically creates outgoing shipments to fill the waiting backorders.

Setting up backorder management includes:

- Enabling the preference.

- Configuring the two automation schedules.

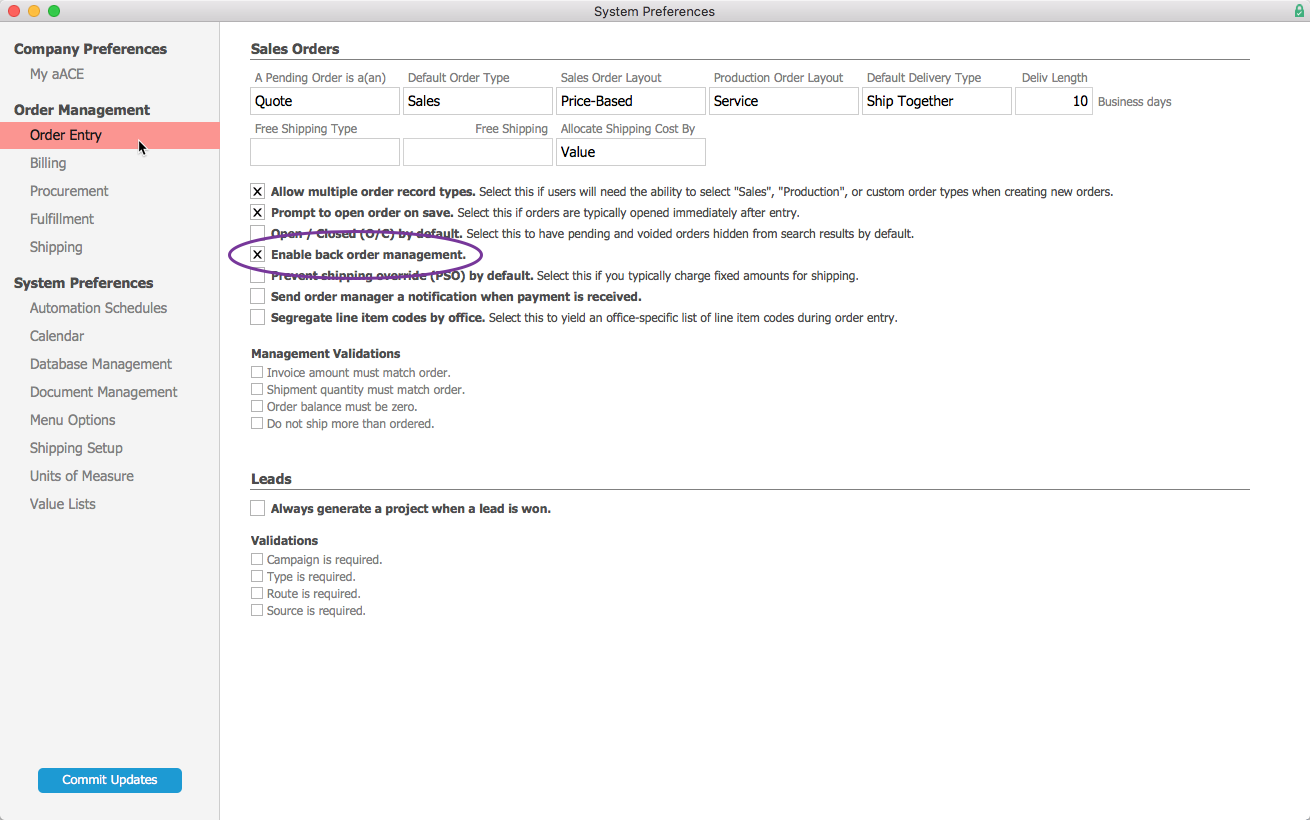

Enabling the Backorder Management Preference

Because effective backorder management hinges on accurate inventory records, this feature is typically not enabled when aACE is first deployed. When your organization is ready, you can easily activate this feature:

- Navigate from Main Menu > System Admin > Preferences > Order Entry.

- Mark the flag to Enable back order management.

- Click Commit Updates.

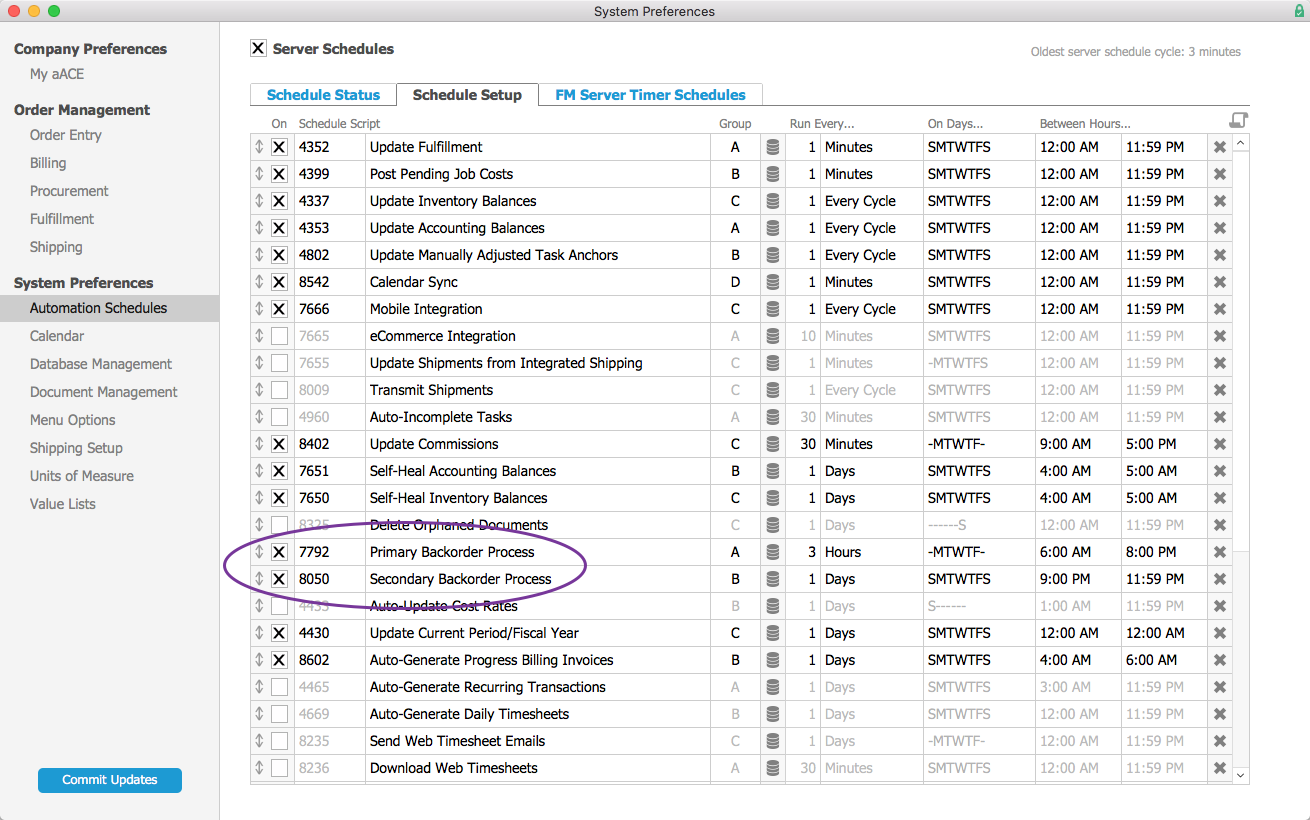

Configuring the Automation Schedules

The aACE scheduling engine helps things run smoothly for end users, while still accomplishing tasks on the time-frame best suited to your organization. It uses two schedules to determine when aACE automatically checks for and processes backorders.

- Navigate from Main Menu > System Admin > Preferences > Automation Schedules > Schedule Setup tab.

- Mark the flags for these two options:

- 7792 — Primary Backorder Process

- 8050 — Secondary Backorder Process

- Configure the schedule settings so each process runs at an appropriate time (see below).

- Click Commit Updates.

Scheduling the Backorder Processes

The Primary Backorder Process evaluates incoming shipments and generates backorder shipments. You can run this process more frequently (e.g. every 30 minutes).

The Secondary Backorder Process evaluates changes from inventory adjustments, voids, returns, etc., and fulfills backorders from the Available balance. This process should run less frequently. This is because it evaluates updates that are less stable. For example, a user might void an order, releasing inventory back into the the Available count. But that might only be a momentary spike because she intends to create a new order which will require that inventory.