After you configure aACE for inventory tracking, it can display inventory counts and values in real time. You will see values and counts change in the various modules as stock is ordered, received, shipped, etc.

aACE uses a seven-step inventory flow, focused on line item codes and inventory lots. As an example here, we trace how the system uses the Last-In-First-Out (LIFO) method to track inventory for a math textbook.

1. Line Item Code Screen Before Purchasing Inventory

At first, the Line Item Code detail screen shows that no inventory exists for this textbook. On the Offices tab though, the Target field is set to 100 and the Replenish Balance is 10. This means any time the inventory balance is 10 or less, aACE is set to automatically generate a purchase order or made-to-stock order that will replenish the balance to the target of 100.

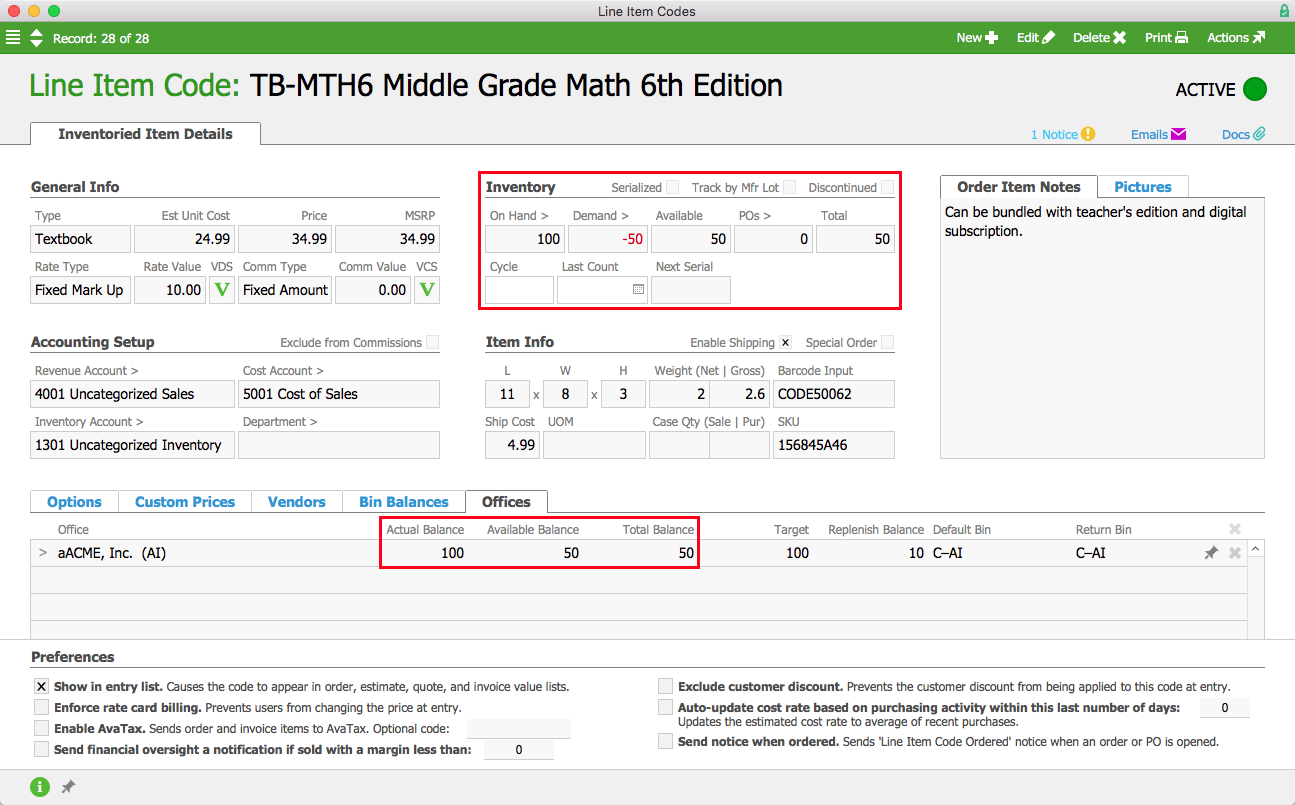

2. Line Item Code Screen After Purchasing Inventory

A purchase of 100 textbooks has been placed and executed. These items are now available for order.

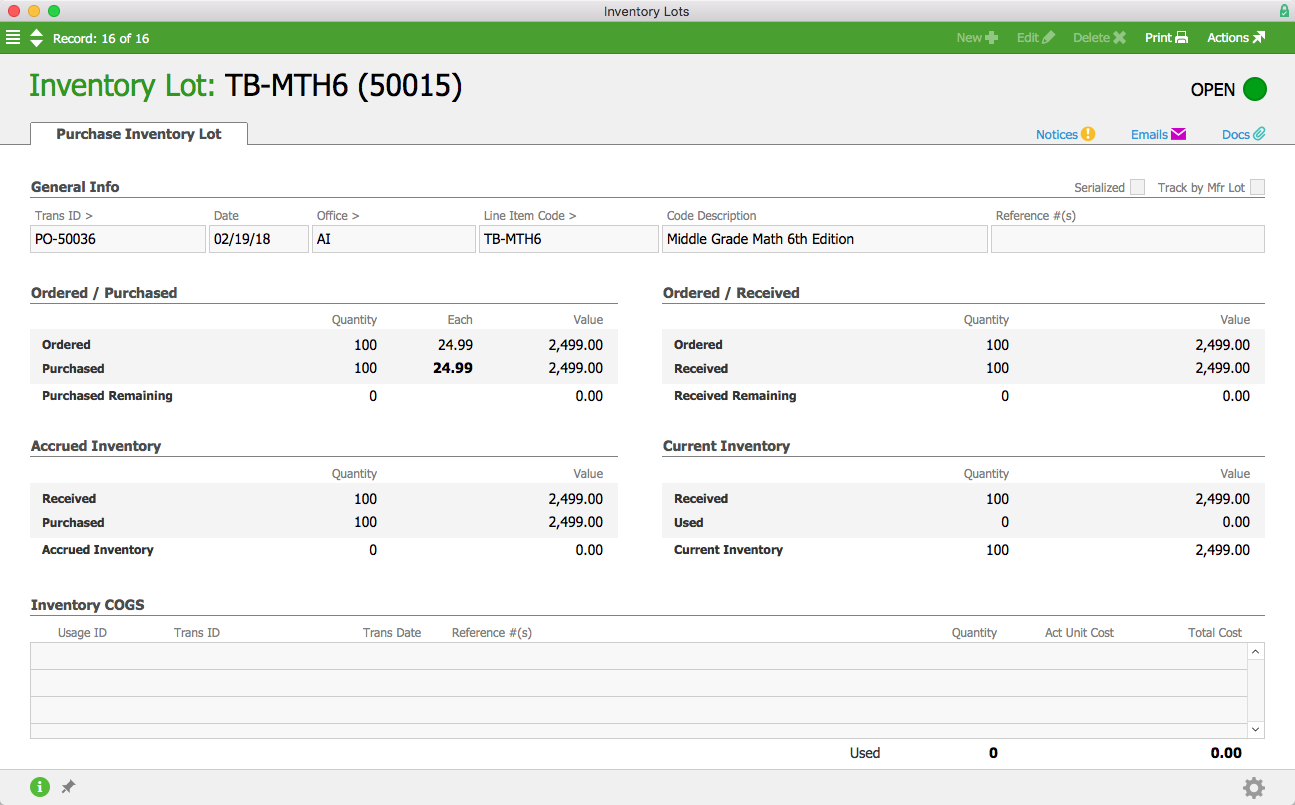

3. Inventory Lot After Receipt and Payment of Inventory

The purchase order for the textbooks also generated an inventory lot record. The inventory lot shows the quantity and value for the number ordered and purchased, as well as for the current inventory.

Note: No sales orders have been placed against the lot shown here. Also, total lot value can be affected when a purchase order is placed, but is then executed with two different purchases on two different dates at two different costs.

4. Line Item Code Screen After Sales Order is Opened

A new order now creates a demand for 50 textbooks, leaving the remaining 50 as available.

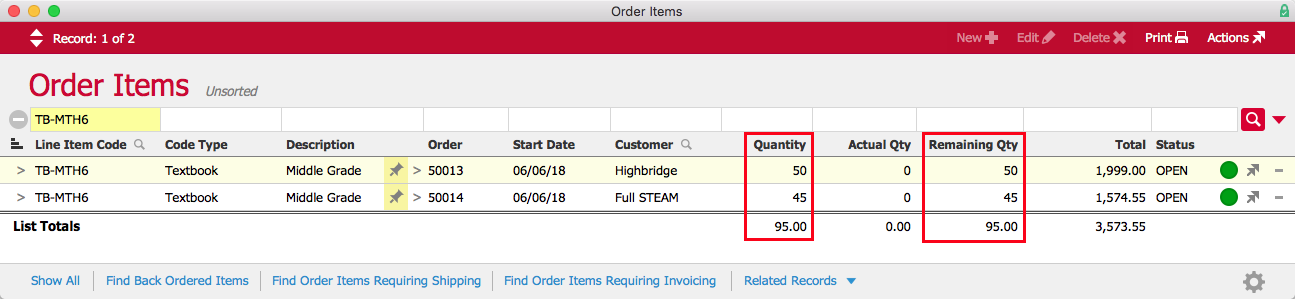

5. Orders Against Textbook Inventory

The initial sales order for 50 textbooks, plus a new sales order for 45, are listed on the Order Items module. Neither order has shipped yet, so the 95 textbooks currently remain in inventory.

6. Line Item Code Screen After Replenishing PO

This screenshot shows the math textbook inventory levels after a replenishing PO has been opened:

- On Hand shows there are still 100 textbooks in physical inventory.

- Demand shows 95 textbooks are already assigned to orders (the two which haven't shipped yet).

- Available shows there are 5 textbooks in inventory that are not currently part of an order.

- POs shows that a purchase of 95 textbooks is already underway to replenish the total to the Target value.

- Total shows that the estimated available count (5 in physical inventory, plus 95 on order) matches the Target value.

7. Textbooks Inventory Lot Allocation

The inventory lots module now shows that LIFO inventory allocations have been placed against our last purchase of 95 units (after the orders have closed and the COGS process has run).

Tips

You can forecast inventory demand using reports from the report pack. Navigate to Menu > Order Setup > Line Item Codes > (select desired LIC) > Print > Open Report Selector > Bill of Materials Forecast (All Offices). This is most informative for assembly line items.